2022 wholesale price Light Pole - Hot Dip Galvanized Street Pole Light Pole – Helios Solar

2022 wholesale price Light Pole - Hot Dip Galvanized Street Pole Light Pole – Helios Solar Detail:

Product Date

| Model Number | TXTLP-03 |

| Material | Usually Q345B/A572, Q235B/A36, Q460 , ASTM573 GR65, GR50 , SS400, SS490, ST52 |

| Minimum Yield Strength | > = 235n / mm2 |

| Spare Parts | Parts for connection or installation |

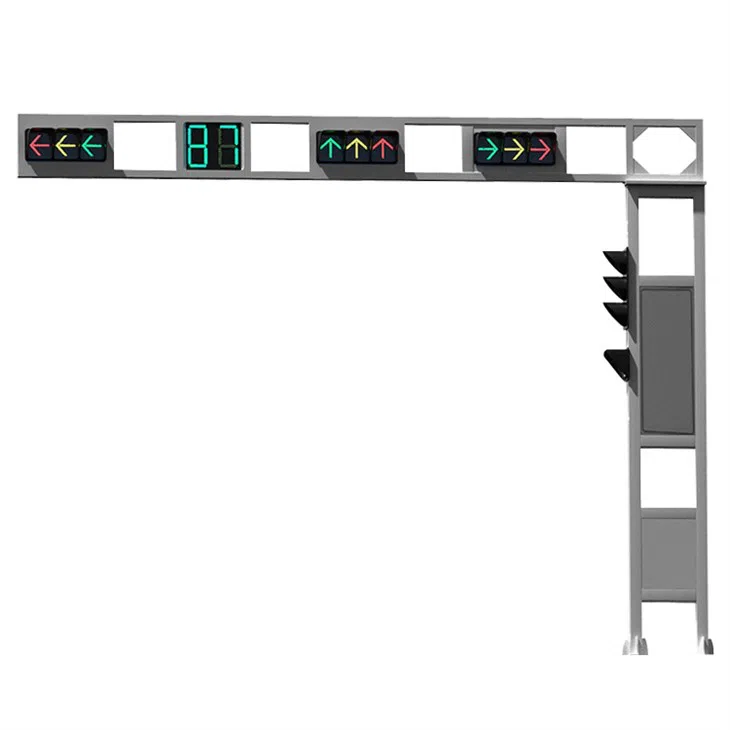

| Pole Shape | Conical, octagonal, square, cylinder |

| Welding Standard | AWS D1.1, both internal and external welding |

| Joint of Poles | Insert mode, inner flange mode, face to face joint mode |

| Wind resistant grade | 36.9m/s |

| Design basis | CECS236:2008 |

| Basic wind pressure | 0.65KN/m |

| Weld grade | The section weld is a secondary weld and the fillet weld is a secondary weld |

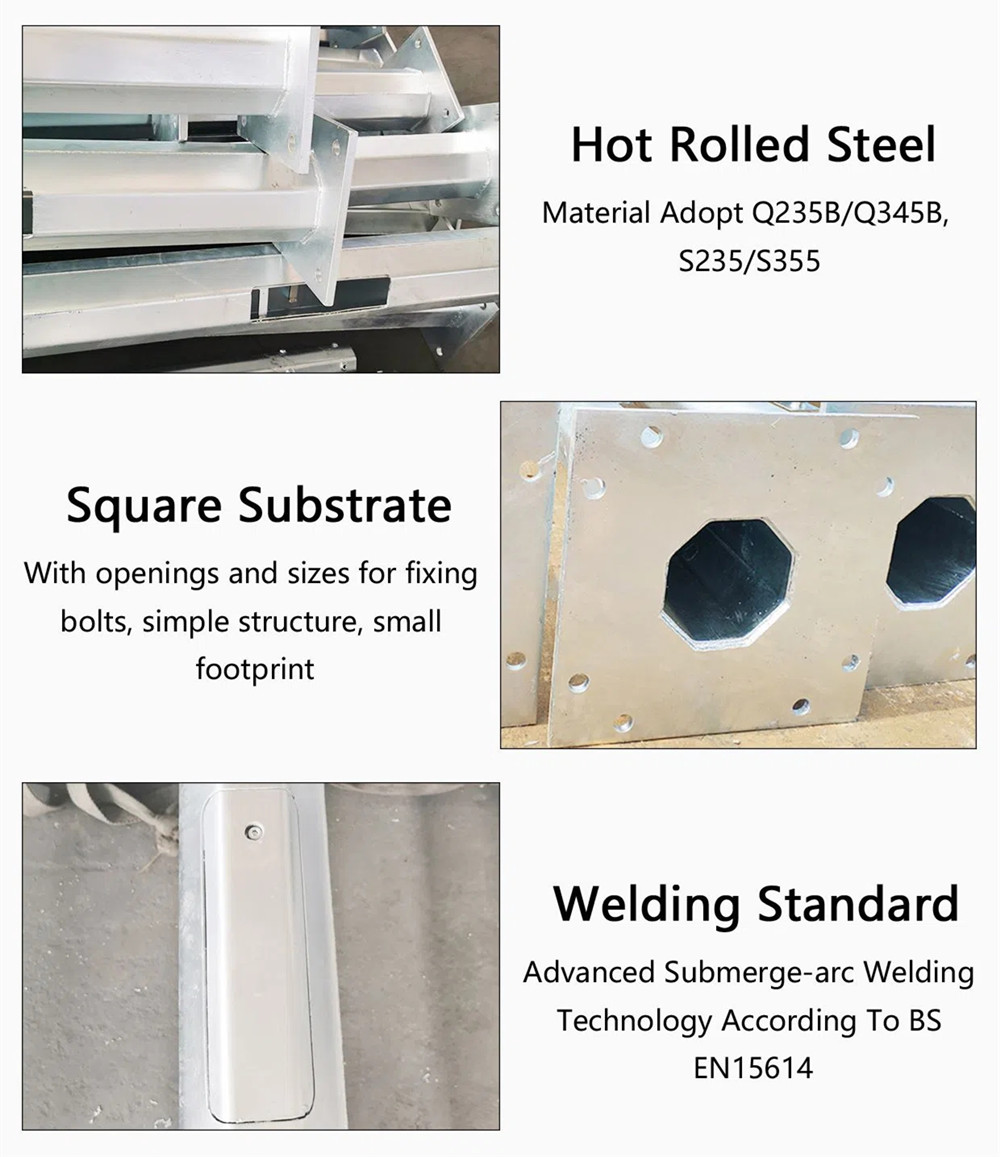

Product Details

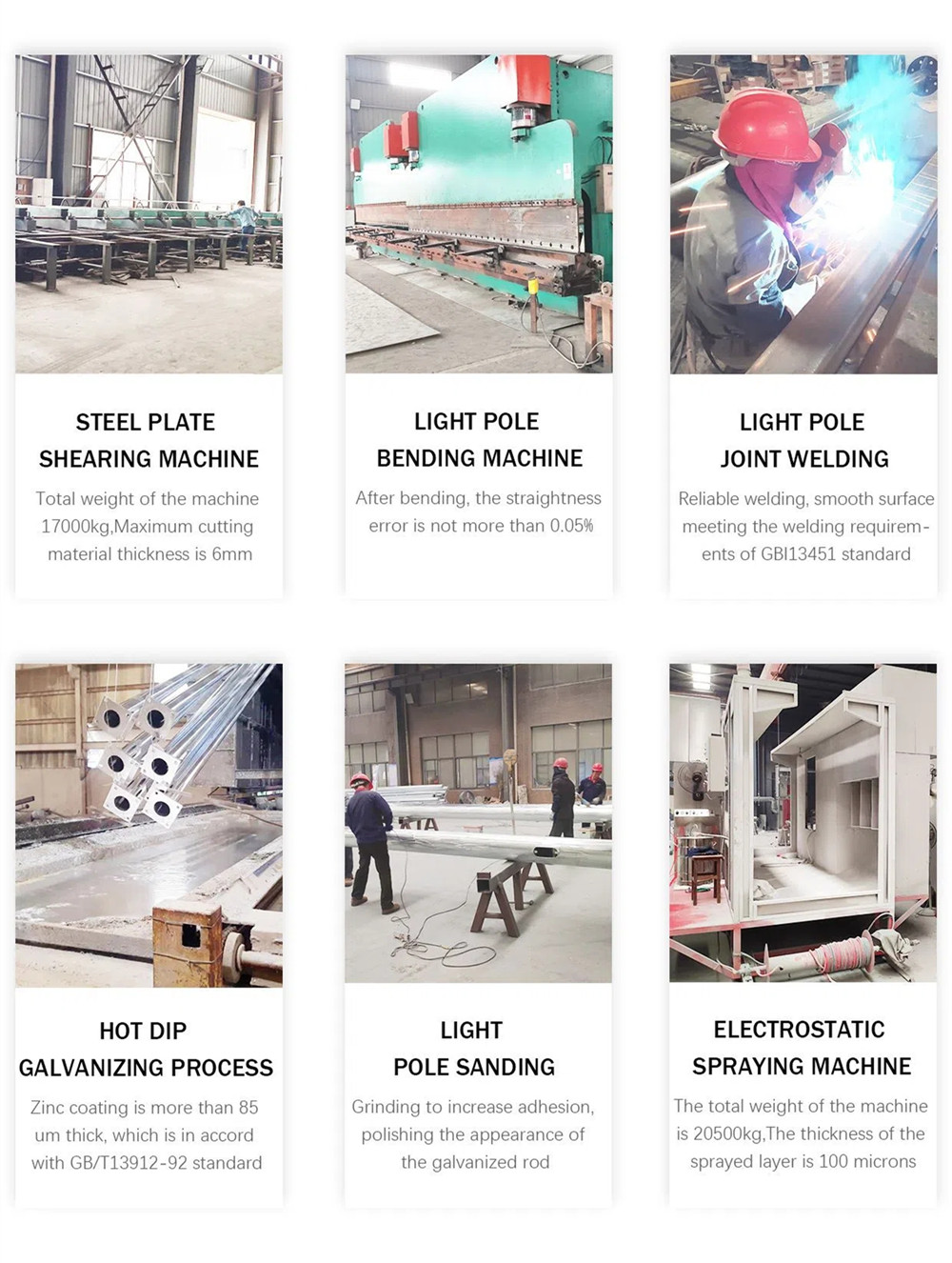

Production Equipment

To assure our products qualified,we take steps as follows :

1. Management team: We have employ the foreign export to take charge of the overall management, especially the technical management and quality management .

2. Introducing ISO management, We are award ISO 9001:2008 certificate . .

3. QC inspection: It is our company policy that all the finish product should be inspected by our specialized QC in every manufacture steps and before every shipment”

Excellent performance:

Because of the long and thin shape, closed polygonal section and apply of high strength steel material, these steel poles have excellent durability. They can withstand the extreme condition, such as the frost climate, unbalanced loads, or breaking of wire.

Installation:

The designing weight of the steel poles are usually relatively light, and is good for the operation, transportation, assemble and installation.

Environment:

Since the long and thin straight line shape.the steel pole from Milkyway Steel Poles are easily intergrated into the landscape. At the protected areas(mountains), the installation of steel pole will not influence the aesthetic solution of the scenic spot.

Maintenance:

The hot dip galvanization trearment can increase the service life of the steel polewithout the environmental pollution and no need for other daily maintance. The following described types are specially designed for Africa Market which can meet the regulated height and load standard of France electricity power company.

Production:

Our steel pole is bend to form to the polygonal(conical) section firstly. Then it is welded by the automatic submerged-arc welding machine. Thirdly the top cap,strip and base plate will be welded to the pole. And finally other accessories (support brackets, ladder support, etc.) will be welded to the pole shaft.

Galvanization:

The galvanization of the steel pole are under strict control. Galvanization is achieved by immersion in a molten zinc bath(450°) after pre-treated(dipping)

FAQ

1. Q: Are you a factory or trading company?

A: We are factory established for 12 years, specialized in outdoor lights.

2. Q: Where is your factory located? How can I visit there?

A: Our factory is located in Yangzhou City, Jiangsu Province, China, about 2 hours drive from Shanghai. All our clients, from home or abroad, are warmly welcome to visit us!

3. Q: What’s your main product?

A: Our main product is Solar Street Light, LED Street Light, Garden Light, LED Flood Light, Light Pole And All Outdoor Lighting

4. Q: Can I try a sample?

A: Yes. Samples for testing quality is available.

5. Q: How long is your lead time?

A: 5-7 working days for samples; around 15 working days for bulk order.

6. Q: What’s your shipping way?

A: By air or sea ship are available.

7. Q: How long is your warranty?

A: 5 years for outdoor lights.

Product detail pictures:

Related Product Guide:

We always do the job to be a tangible group making sure that we can provide you with the top top quality as well as ideal value for 2022 wholesale price Light Pole - Hot Dip Galvanized Street Pole Light Pole – Helios Solar , The product will supply to all over the world, such as: Hungary, Latvia, Greece, Our products are very popular in the word, like South American, Africa, Asia and so on. Companies to "create first-class products" as the goal, and strive to provide customers with high quality products, provide high-quality after-sales service and technical support, and customer mutual benefit, create a better career and future!

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.

Send your message to us:

PRODUCT CATEGORIES

Focus on providing mong pu solutions for 5 years.