Double Arm Light Pole for Highway Street

Product Description

Feature:

This Double arms road street light pole,constructed from stainless steel 304, is 9 meter (30 feet) high with a wall thickness 3.0mm (0.118 inches) .The butt diameter is 188mm(7.4 inches )and tapers to 80mm(3.15 inches ) in diameter at the top.The design of this light post,brings a uniform lighting experience to a large space and solve potential obstacles to traffic to increase safety .They are used in parking lots, downtown areas, neighborhoods, walkways and building grounds.

Pole:

The pole shaft is round tapered,made from austenitic stainless steel 304 steel plate of one-piece construction,the seam of the post is welded by plasma welding automatically equipment.

Luminaires Arm:

The luminaire arms are made of four stainless steel round tubes . Four ss round tubes are a separate section .The connecting part of a lamp arm are welded by Submerged Arc Welding process.

Light Pole Hand Hole:

Each light pole hand hole includes a light pole access cover and cover attachment hardware.Pole assembly is provided with a 120*300mm rectangular hand hole.

Base Plate:

The base plate is square with four slotted holes for anchor bolts, fabricated from ASTM A240 stainless steel .The base plate and pole shaft is circumferentially welded top and bottom.

Light Pole Anchor Bolts:

Anchor bolts are rolled from galvanized steel Q235B .Each anchor bolts shall include:four steel hot dip galvanized anchor bolts each with two nuts and two flat washers sized to match the anchor bolts.

Finish:

Standard finish for this double head stainless steel pole light is specified as satin brushed finished.Additional finished option ,including powered coat finished and polished finish,gold titanium finished are available upon request.

Other Options:

The following options are available. Please consult our sales representative for details:

Hardware, custom tenon sizes, custom colors, luminaries, custom pole heights, additional handholes, custom base plate dimensions.

Basic Info.

| Model NO. | TXSLP |

| Thickness | 2.5mm,3mm,3.5mm,4mm,4.5mm,5.0mm |

| Design | ODM /OEM |

| Process 1 | Roll Pole |

| Process 2 | Advanced Submerge-Arc Welding Technology |

| Process 3 | Hot-Galvanized |

| Process 4 | Polish Pole |

| Process 5 | Straighten Pole |

| Process 6 | Powder Coating |

| Painting Color | Any Ral Color |

| Warranty | 10years |

| Certificate | ISO, RoHS |

| MOQ | 1 PC |

| Monthly Supply | 10000PCS |

| Transport Package | Bubble Bags and Cotton |

| Specification | 3m 4m 5m 6m 8m 10m 12m 20m |

| Trademark | NO |

| Origin | China |

| HS Code | 7308900000 |

| Production Capacity | 10000 |

Product Description

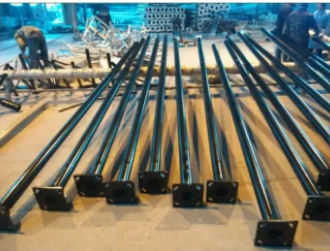

BLACK POLE

Height :3m-30m

thickness:2.5-12mm

diameter :see situation

flange plate:see situation

process: just roll and weld

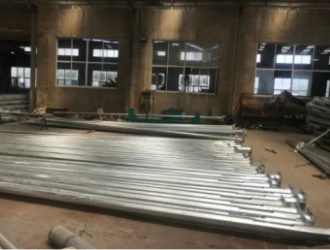

HOT-GALVANIZED POLE

Height :3m-30m

thickness:2.5-12mm

diameter :see situation

flange plate:see situation

process: do hot galvanzied& deactivation

HOT-GALVANIZED&POWDER COATING POLE

Height :3m-30m

thickness:2.5-12mm

diameter :see situation

flange plate:see situation

process: do hot galvanzied& powder coating

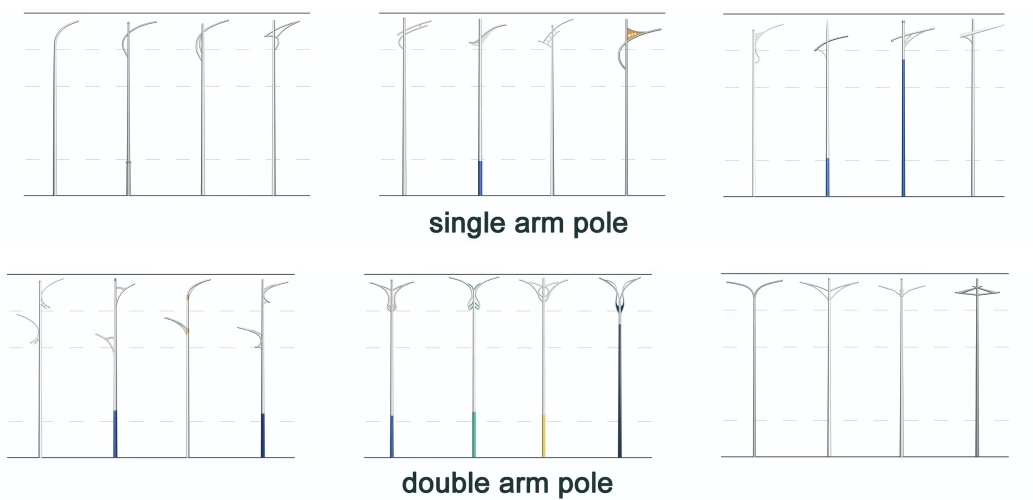

Design of Pole

Production Details

Packing Details

FAQ

1.Q:Are you a factory or trading company?

A:We are a factory.

2.Q:Where is your factory located? How can I visit there?

A:Our factory is located in Yangzhou City, Jiangsu Province, China, about 2 hours drive from Shanghai. All our clients, from home or abroad, are warmly welcome to visit us!

3.Q:What's your MOQ?

A: 1 set.

4.Q:How does your factory do regarding quality control?

A:100% of the lamps will be tested and keep lighting for 24-72 hours to test its quality reliability , and we will also test its temperature after 24 hours' lighting.

Then after it is cool we again test 100% of the lamps to see if it still work well . Each lamp should pass all these QC procedures before shipping to customer.

Certification

Send your message to us:

PRODUCT CATEGORIES

Focus on providing mong pu solutions for 5 years.